3200cc Mighty Mouse

Page 4

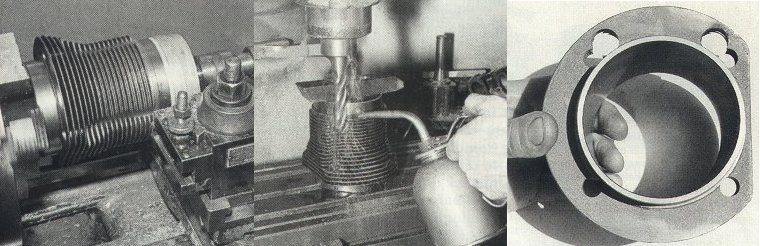

Above, left and center, the Cima cylinders are modified slightly, beginning with shortening them on the lathe by removing approximately .300-in. from the bottom seating areas. Then, the cylinders are numbered for placement on the engine, as the stud pattern is not symmetrical and requires that the bottom stud holes be redrilled and notched similar to that found on the stock cylinders.

The photo above, right, clearly shows how the stud holes are modified for the stock Corvair stud pattern. One of the last things done is honing the cylinders true so the rings have a good seating surface.

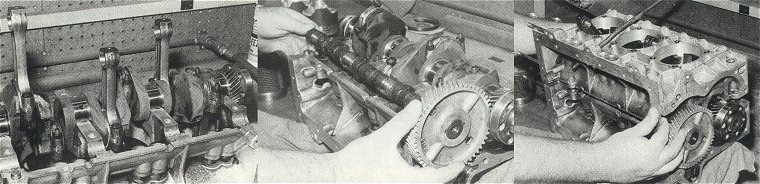

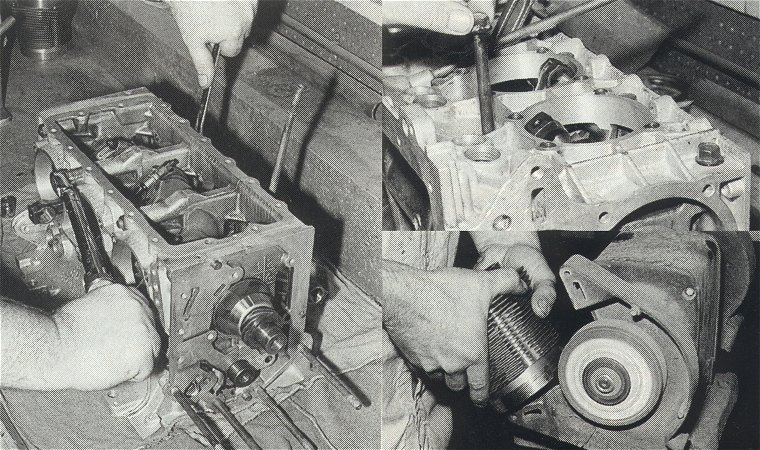

At this point the dry assembly procedure begins. The first order of business is hanging the rods on the crank, then installing the cam and gear assembly, and then bolting the case halves together. The first time the engine went together, we simply checked for interference between the rotating components. This is also a good time to check the deck height, and set it for the desired compression ratio. In this case, the customer's engine was set at 9.0:1, which required the use of .060-in. thick copper head gaskets along with .606-in. deck height. Cylinder volume at TDC was 10.45 ccs. You'll notice that the stock thru-bolts are used during the dry assembly period, but upon final assembly we switched over to the heavy duty ARP aftermarket case studs.

You'll want to be sure that the engine case halves are fully torqued when checking clearances between parts. The cylinder skirts get a notch ground into them, similar to stock, to provide clearance for reciprocating connecting rod.