3200cc Mighty Mouse

Page 7

The next order of business is installing the valve covers. Not shown in photos, but very important just the same, is the oil pump maintenance. It's advised to disassemble the oil pump, clean it very well, check for wear on internal parts, and reassemble it with care before reinstalling it on the engine.

Remember that the oil is the lifeblood of the engine, and the pump's job is to make sure there's enough oil pressure to keep the engine healthy under extreme conditions.

the heads and valvetrain area fully assembled, the adapter plate and flywheel are bolted up. Before the front cover is fitted and harmonic balancer installed, the oil pump is cleaned, checked, blueprinted, reassembled and reinstalled. Then the oil pan, top cover and stock shrouding are installed. Finally, the exhaust and intake systems were custom fabricated for the turbocharger, while the long block was installed in the buggy frame. This is a whole separate story in and of itself, which we will not discuss at this time - maybe in a future issue. We're sure those of you who prefer running Corvair engines will agree this is a ton of work, but you can't beat this method as a dependable way to increase the power and longevity of Chevrolet's horizontally opposed six-cylinder engine.

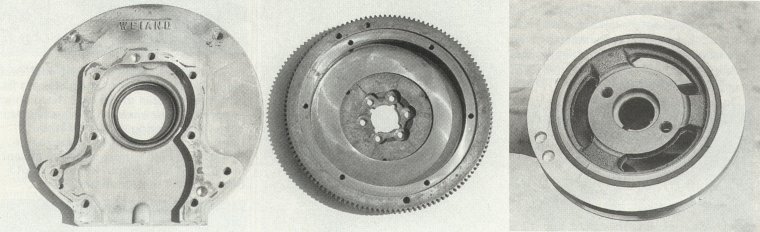

Above, left to right, the Weiand adapter plate for VW style bellhousing, the flywheel and the harmonic balancer. This particular balancer has a nodular iron center with a steel outer ring. It also has a slightly wider belt groove for better belt retention. A balancer is critical to help cancel out any damaging harmonic vibrations with the engine.