3200cc Mighty Mouse

Page 6

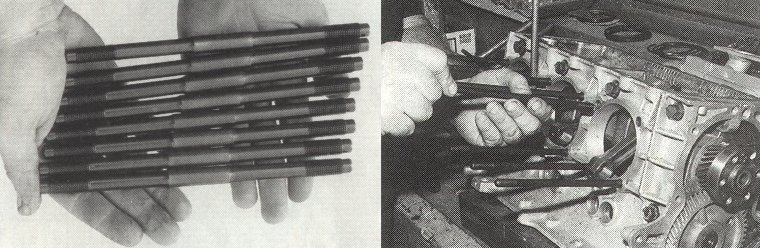

Left, a close-up of the HD ARP case studs. These studs form a slight press fit in the saddle area of the case, forming a permanent lock between the two halves of the case bearing saddles. Without them, the saddles are free to move due to heat and high torque stresses present in modified high-output engines.

The photo above, right, shows the 10mm head studs.

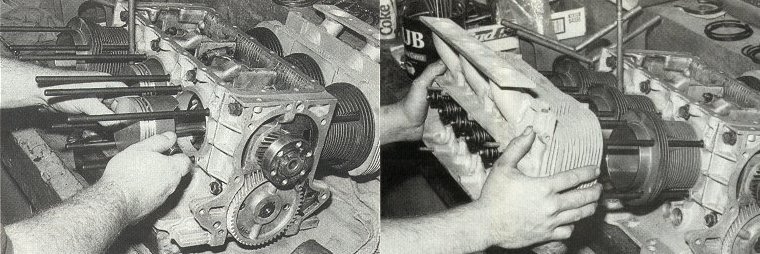

After the head studs are installed, and the Cima pistons are mounted on the connecting rods, the cylinder heads are installed.

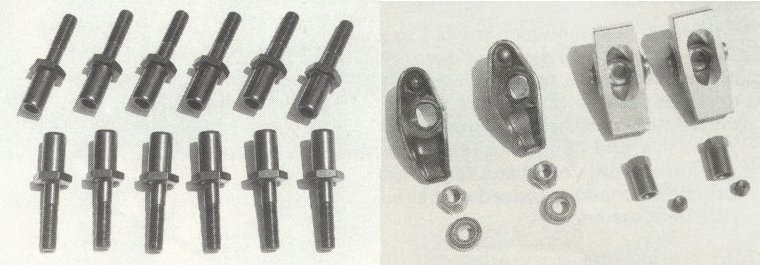

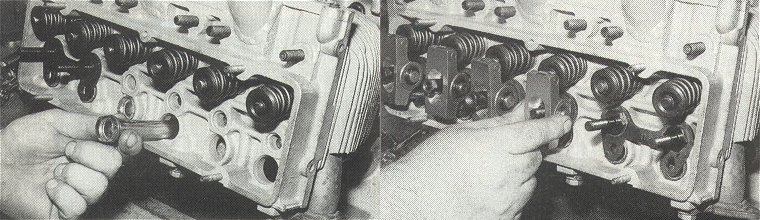

The cylinder heads utilize chrome moly hardware and race quality rocker studs (above, left). These are exact stock replacement items, but are produced from chrome moly, heat treated and black oxide coated. 6061 needle bearing roller tip rockers are a must (see above and below, right), and replace the stock units, while claiming to increase power by 10-15 hp. These trick rockers are a direct bolt-in replacement, having the correct 6.4° and 4.2° rocker angles.

The pushrod tubes and pushrods are installed prior to installing the head nut and rocker stud combination hardware. Everything is then topped off with a set of billet aluminum rockers arms, above right.